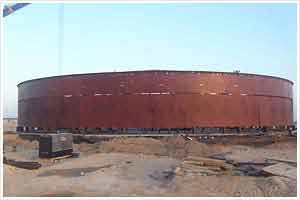

- If the ratio of Height to Diameter is more than 1, seek

assistance for Technical support.

- Arc spacing between trestle SHALL NOT EXCEED 3.00 m, otherwise

immediately contact Technical support.

- The maximum LOAD on hydraulic jack SHALL NEVER EXCEED the safe

working load.

- Safe bearing capacity above the tank bottom plate (below the

trestle base plate) shall be minimum 1.45 N/mm2.

Overload or misuse of Jacking equipment can result into PROPERTY

DAMAGE, BODY INJURY OR DEATH. Before choosing the kind and number of

jacks for any tank project, or before operating the jacking equipment,

read our instructions and the Safety section carefully, and understand

the information contained therein.